How might we use circular economy principles to rethink the storage, delivery and dispensing of tablet medication?

In the pharmaceutial industry plastic is one of the most used materials, especially with blister pack medication. I aim to propose a biodegradable plant based plastic blister pack. Improving the system in place and replacing with a strong circular economy system supporting the enviroment.

The Brief

Without The Waste

This brief is to design a new system for the failing one which has been in place for years. With the circular economy in mind I’m tasked to rethink the packaging and design of the tablet medication business and its affects on the enviroments.

I am propsing a system which is designed to substainably support the enviroment as well as the economy. producing a user and eco friendly blister packet and storage system.

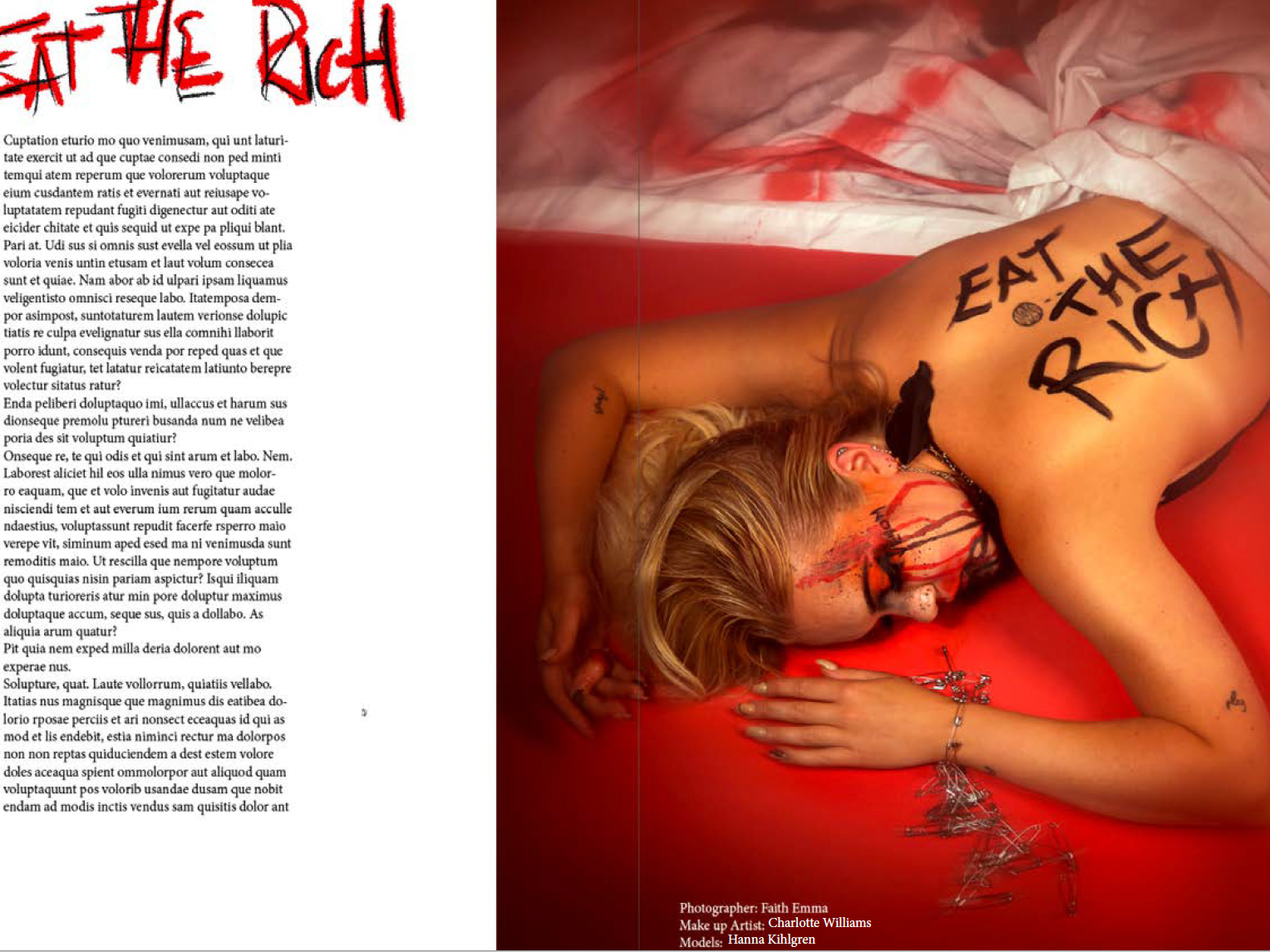

Circular Economy

Circular Economy is made of four main principles Recycling, Remanufacturing, Refurbishing and Reuse. My aim objective is to have all four represented in my outcome product

Primary Research

CRA, is a design company I came across based in brazil. The designers created a machine which makes fresh orange juice in front of the customer and creating a bio plastic cup in from the discarded orange peel with a 3D printer. Which has inspired my idea.

Another designer Danny Handley, who did product design at university and created a product from orange peel and starch. To store food keeping it fresh, in mimicking what a orange does naturally for its fruit. I plan to use local companies to start with to gather used orange peels. For example, XOXO a new brunch bar in town which makes tons of fresh orange juice each making and just throws away all used orange peels. I want to use the orange peels and recycle them into a second life.

Secondary Research

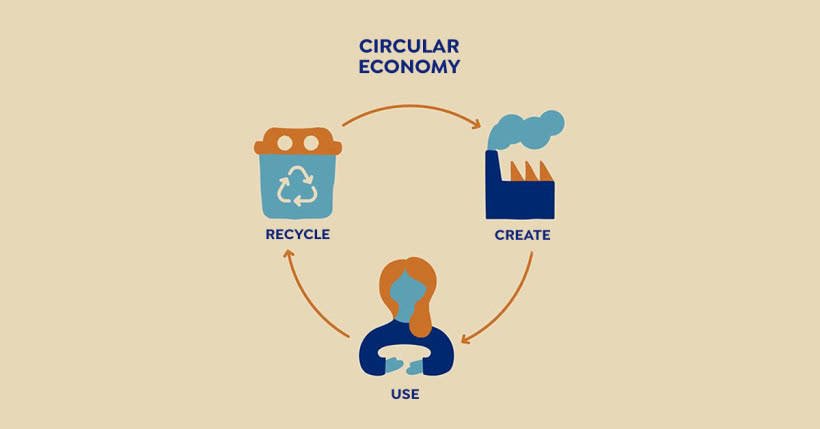

At the moment, blister packs are the most brought/ manufactured product of the pharmaceutical industry. With most not being environmentally sustainable and left in landfills. Which is why I want to use bio plastics as my main resource in creating a better system.

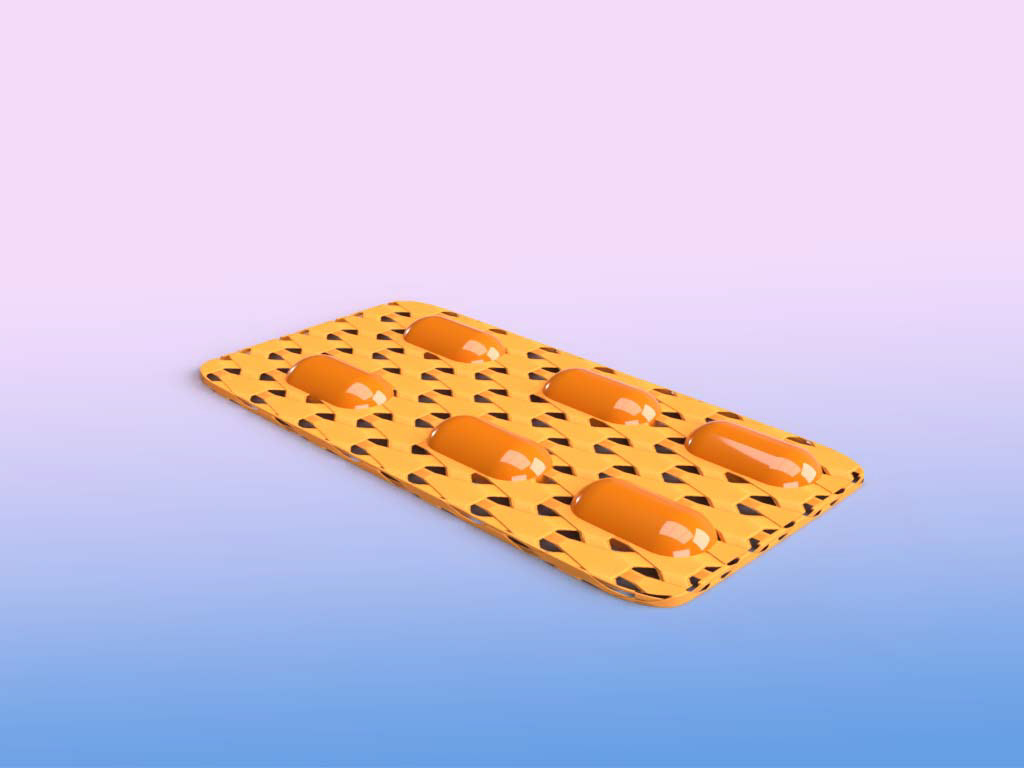

The reason I’m using bio plastics as my main resource is due to the reuse factor of plant life and it is having a full life cycle, a true recyclable product. The way the process works is that the plant is extracted and refined in a factory. This means the plant is heated and melted to a bio plastic resource and converted into the product. To then thrown into decomposed process and reborn into the plant once again. To create the bio-filament ink for the blister pack the system is quite simple. Firstly, I will need to dry the peel out and then crush it into a powder, which can be used in facial treatments as well. The powder is then mixed with PLA, Polylactic acid a thermoplastic which is environmentally friendly. Finally, this creates the bio-filament which can then be printed into my blister packs.

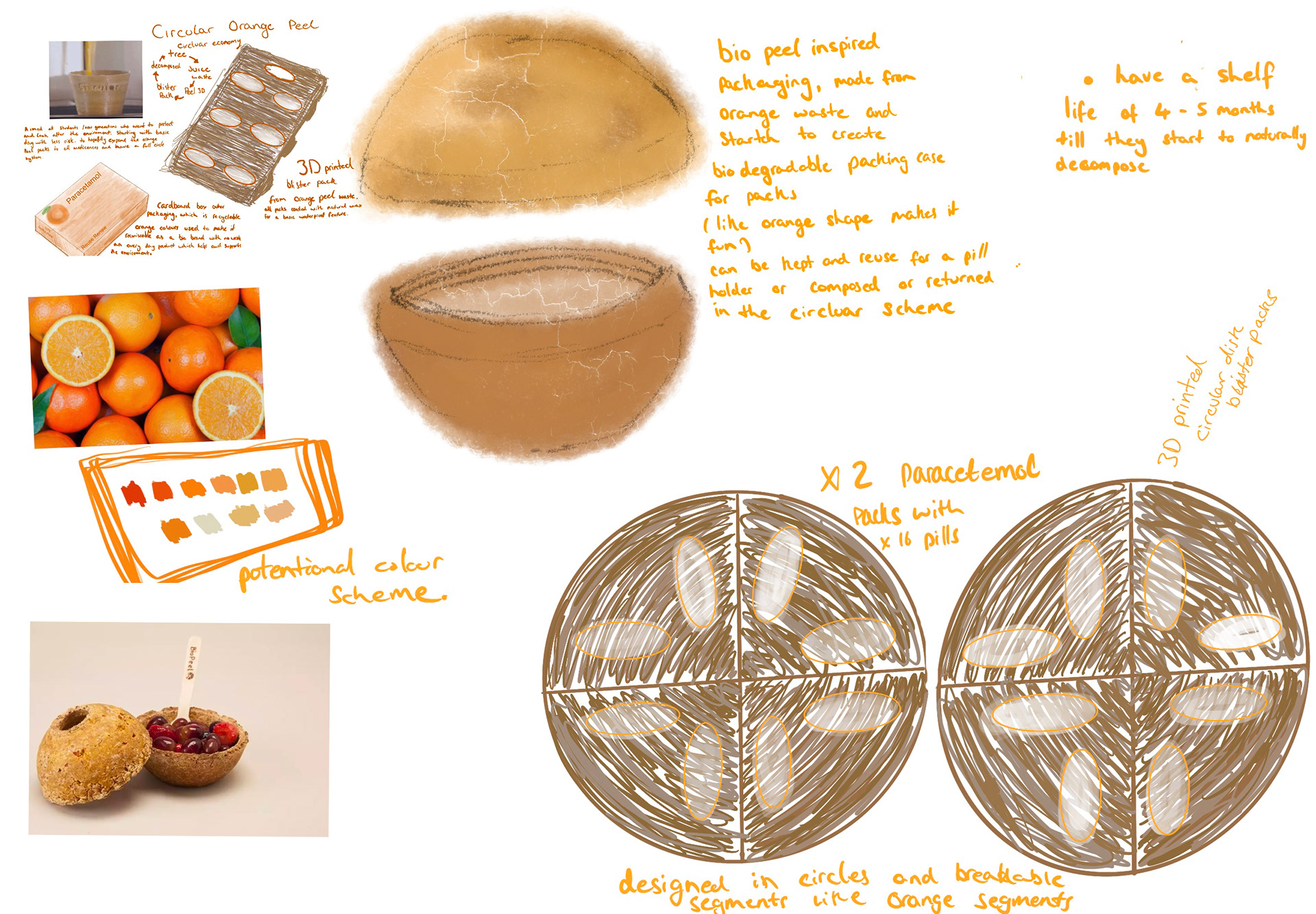

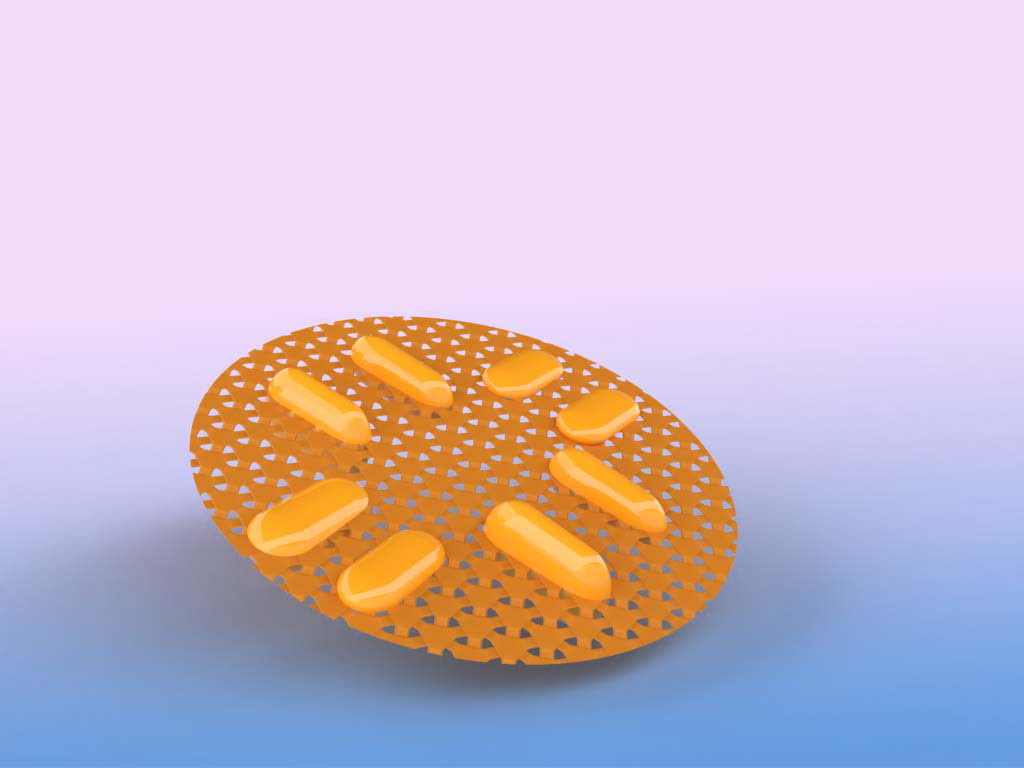

These are two design plans I created for my blister packs. my first design idea, I wanted to create the pack from a 3D printer. Using the blister pack design we all use today. I also wanted to use the natural wax from the orange peel to coat the pack giving the product a natural waterproof coating. For the outer packaging I planned on using a simple cardboard box which was recyclable. For my second design idea I design circular blister packs with breakable segments, inspired by the oranges natural design features. For the outer packaging I changed it to using the bio peel inspired packaging made from orange peel and starch making this product eventually 100% biodegradable.

Final Design and Product

Critical Evaluation

RSA Student Award has been an eye-opening brief and has expand my skill set and knowledge of design. Without The Waste is a brief built to tackle the tablet medication system and design a new way in which it can progress into the future, making it apart of the circular economy.

I enjoyed using Adobe Dimension creating my vision for an eco-friendly blister pack come true. I believe I have succeeded at my aim in designing a system that include all four the main principles of circular economy. I strongly trust in this product working and coming together with all the extensive primary and secondary research I have done about the materials, creating process and practicality.

However, I do believe there’s always room for improvement. With my second design idea, I took the orange shape and its part of the product too far. The sphere shape packaging wasn’t the best idea due to it not being able to store well and becoming a hazard with children. I also feel that I have let myself down with the branding side of this brief, as I haven’t done much. Starting with the name Peel Pills which just didn’t work or tested well with users. I do like the logo I have now as its simple and doesn’t distract from the products USP, being a bio product.

In the future I’d like to investigate different ways which the product can be manufacture, as 3d printers can be slow and if we aren’t producing the same or more as the unsustainable products what’s the point? I will research into different type of printers, but also different ways bioplastic can be refurbished into my bio blister pack design.

This brief has been a Turing point in the way I think about resources and research on proving that the next idea is also physically possible.